Fon: +49 (0) 28 23 / 97 69 - 0

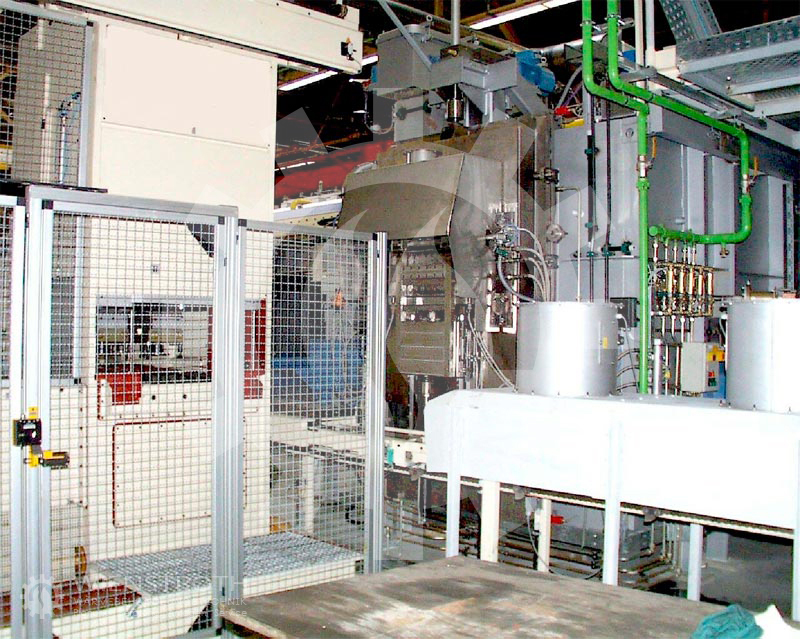

Pusher-type furnace systems are deployed, in particular, in large-scale production.

The high level of reproducibility of the heat treatment results and the level of automation make them particularly cost-effective. Depending on the deployment and the desired throughput capacity, single and multi-line systems are deployed. Combined with the relevant peripheral equipment, such as a tempering furnace and pre-oxidation furnace, washing unit, grate transportation and storage units, as well as process visualisation and documentation, fully automated operation with minimal staff deployment is feasible.

Here are some pictures illustrating this: